In her book The Modern Natural Dyer (1), Kristine Vejar emphasises the importance of keeping baths for scouring, mordanting and dyeing at steady temperatures suited to the dye material and the fibres being dyed. I have often ignored this advice. This is called “cutting off your nose to spite your face” or just downright contrary. Several well known and otherwise valuable dyes are rendered useless with high heat, eg madder. Sometimes/ at full moon I have used a thermometer. This is painful and tedious. I don’t do painstaking/fastidious, aka “anal” very well.

However, a friend recently cleaned out her kitchen and I was able to acquire a very good, almost new, slow cooker with the ability to sear and brown before cooking. This meant I could retire my old slow cooker from the kitchen to the studio to be dedicated to dyeing. I have heard that the way a slow cooker works is to keep the temperature reasonably constant at whatever setting is in use (ie, in my case, at High or Low).

A trial suggested itself. In another week I am, as part of a WAFTA team (2), demonstrating “natural dyeing” at the local agricultural show. I have a lot of yarn already dyed with plants; with and without mordants; with heat and without; solar versus energy I have to pay for; etc.

“Natural dyeing” is championed in social media for a variety of reasons. Some people erroneously advocate the use of plants for dyes as a way of avoiding the use of chemicals. This is silly because of course everything in the universe, including dead and living plants, contains chemicals. Others, more sensibly, point to desirable sustainability, which is achieved as long as the plant materials you are using are in fact harvested sustainably!

I like natural dyeing because the results appeal to my love of muted colour (not everyone’s cup of tea I know) and because it can be a relatively safe way of dyeing (provided care is taken to research the effects and chemical content of the plants themselves and any mordants).

Thinking about what I might do this weekend to supplement my collection of solar-dyed and stove-top plant dyed yarns for the demonstration at the agricultural show, I figured safety and food would be relevant to attendees’ interests.

So…..how about trying something a “little bit fancy” (Aussie joke)? Challenges:

.use food grade colouring and combine colours for a gradient along a skein;

.attempt to control the amount of mixing between colours so that there are crisper breaks between them rather than the more “blended” appearance you get as colours flow together when you lay one skein out and dye with various colours in a low immersion bath;

.assisted only by vinegar and heat; and

.trial the “old” slow cooker in its new role.

Step 1: I wound a 100g (actually weighed 105g) skein of fingering weight sock yarn into five mini skeins each of 21g +/- 3g.

Note 1: The yarn came from Bendigo Woollen Mills and is 80% fine merino and 20% nylon.

Note 2: I didn’t cut the yarn between the small skeins but left them all linked so that after dyeing I could rewind into a 100g (approx. 360 metre) skein.

Step 2: I then soaked all five of the conjoined mini skeins in cold tap water for one hour.

Step 3: Meanwhile I set up five small jars, each a slightly different shape and each having previously held about 200-300g of foods like chutney or mustard or jam.

Note 3: I was limited to somewhat squat jars, having tidied the jar stash the previous week and sent the taller ones to recycling because the squat ones look so much better when filled with chutneys and jams etc. Duh! Five taller jars would have a) enabled me to have a higher water level in the slow cooker water bath and b) enabled me more easily to fit the five jars into the slow cooker.

Step 4: Into each jar I put half a cup of tap water at the temperature it was when it emerged from the cold tap.

Step 5: I then added differing combinations of two different food colourings to each jar.

Jar #1 contained 1tsp of liquid blue food colouring (Maharajah Brand Brilliant Blue No. 133).

Jar #2 contained 3/4 tsp of blue and 1/4 tsp of pink food colourings.

Jar #3 contained half a tsp each of the blue and the pink food colourings.

Jar #4 contained 1/4 tsp of blue and 3/4 tsp of pink.

Jar #5 contained 1 tsp of liquid pink food colouring (Maharajah Brand Erythrosine No. 127) described on the bottles as a rose pink.

Step 6: Dipping white paper into the jars showed me that I had a pretty good and even range of colours, although there was breaking over time in Jars 2,3 and 4. I figured that my process would prevent too much breaking on the actual yarn.

Step 7: Each of the pre-soaked mini skeins was immersed in a jar and poked a bit to ensure the dye was in contact with all the fibre. I then added another one-quarter cup of water and one tsp of white vinegar to each jar and placed all of them into the pre-heated (on Low) slow cooker.

Step 8: After one hour I checked and thought they were not steaming enough. Most of the red had disappeared into the yarn but the jars with blue seemed to still have some blue in solution. I added another tsp of vinegar to each jar and raised the setting to High. I left that for an hour and then turned off the heat. Cooker and contents were left to cool over night.

Step 9: I removed the yarn from the five jars, noting that the water in each was quite clear. Rinsing was easy with not a lot of blue left unattached to the yarn and no pink.

Step 10: Drying and rewinding into a skein. Et voilà!

(1) Vejar, Kristine. The Modern Natural Dyer, Stewart, Tabori and Chang, New York, 2015

(2) The Western Australian Fibre and Textile Association (WAFTA) : https://www.wafta.com.au

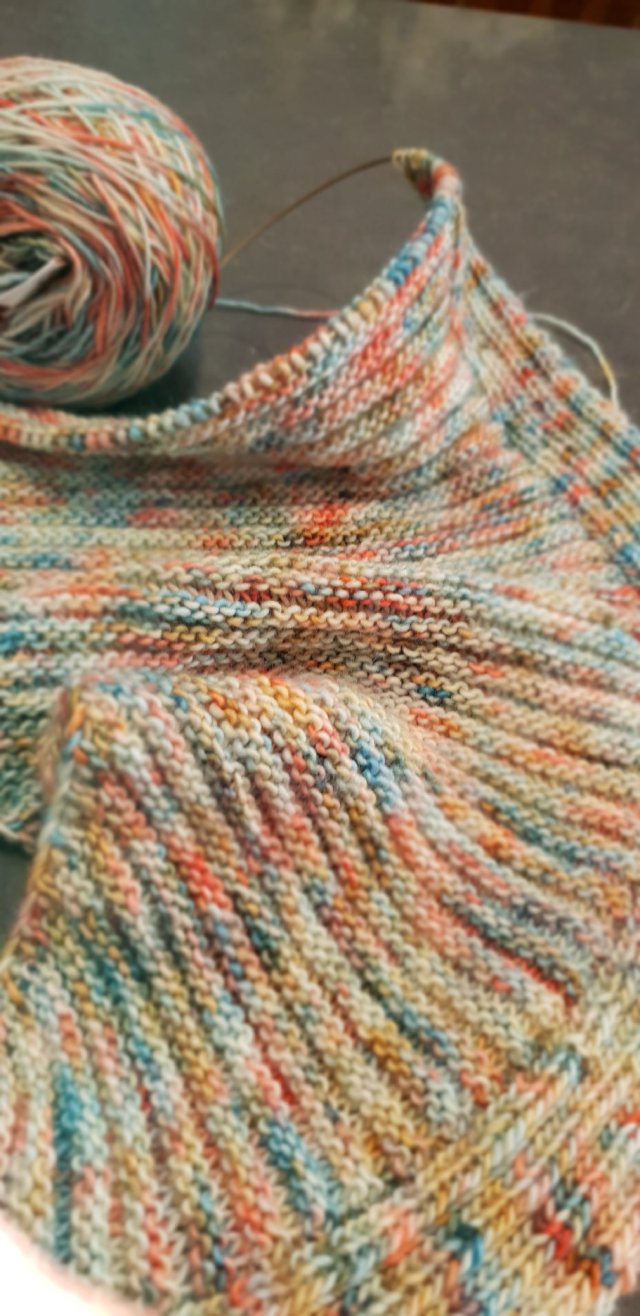

I’ve called this blog Dream Time Shawl because that’s what its designer Teresa Dair called it.

I’ve called this blog Dream Time Shawl because that’s what its designer Teresa Dair called it.